Frequently Asked Questions

We Have The Answers!

Answers to everything you need to know about our HDPE conduit offerings.

If you don’t see the answer to your questions, contact us and we’ll get you an answer!

Product Basics & Definitions

What does HDPE stand for?

HDPE stands for High-Density Polyethylene, a durable, lightweight, and flexible plastic material ideal for conduit applications.

What is the difference between HDPE conduit and traditional PVC conduit?

HDPE conduit delivers remarkable flexibility, easier trenchless installation, and superior impact and chemical resistance—especially in cold weather—compared to PVC. HDPE is lighter, costs less to handle, and offers a long lifespan (over 50 years), helping reduce long-term replacement costs. In contrast, PVC is generally stiffer and heavier, with less resilience to harsh environmental conditions.

What does SDR stand for?

SDR means Standard Dimension Ratio. It is the ratio of the conduit’s outer diameter to its wall thickness. The lower the SDR number, the thicker the wall and the stronger the conduit.

Can HDPE conduit be used for both electrical and fiber-optic applications?

Absolutely. Our HDPE conduit is engineered to protect both fiber optic and electrical power cables across a wide range of applications—from telecom and broadband installations to SCADA, highway lighting, and municipal infrastructure.

Technical Specifications

How does conduit wall thickness rating (e.g., SDR) impact pressure or load-bearing capacity?

SDR reflects wall thickness relative to outside diameter. A lower SDR (e.g., SDR 9) indicates a thicker wall—offering greater resistance to soil pressure and mechanical stress. A higher SDR means thinner wall and more flexibility. Selecting the right SDR requires evaluating soil conditions, installation length, expected loads, and application needs.

How does temperature affect HDPE conduit performance?

HDPE maintains dimensional stability and impact resistance across a broad temperature span—remaining durable in both hot and cold environments. It is commonly used in harsh climate installations.

What standards and certifications does your HDPE conduit meet?

We adhere to ASTM F2160, ASTM D3350, SUDAS Spec 8010.2.01, and AASHTO M294 specifications. Every product is tested for dimensional accuracy, tensile strength, and ovality to meet or exceed ASTM standards.

What are the cost advantages of using HDPE compared to other conduit materials?

HDPE offers lower handling and installation costs due to its light weight and flexibility, which reduce labor time and the need for heavy equipment. Its durability and long service life also reduce long-term maintenance and replacement expenses.

What is the NEC conduit fill guideline?

The National Electrical Code (NEC) sets guidelines for the maximum percentage of conduit interior space that cables can occupy. Following these guidelines ensures safe operation and prevents overheating.

What is the recommended casing size?

The casing size depends on the cable count, cable size, and NEC fill requirements. Our team can help you determine the correct casing size for your project.

Installation & Applications

What installation methods are compatible with HDPE conduit?

HDPE conduit works for trenching, direct burial, plowing, horizontal directional drilling (HDD), and aerial installations. Its flexibility and strength make it suitable for virtually any standard installation method.

What lengths of HDPE conduit are available and can special lengths be ordered?

We offer standard reel lengths, and our in-house manufacturing capability allows for custom lengths and configurations tailored to your project.

Pricing & Ordering

Why is it important to get a quote for HDPE pricing?

HDPE conduit pricing can vary based on raw material costs, order volume, and custom specifications. Getting a quote ensures you have accurate, up-to-date pricing for your project.

What is the lead time and order minimum for HDPE conduit?

Lead time varies depending on specifications and quantities. Once your order is ready, we can load it onto a truck at your scheduled date and time for prompt delivery to your job site.

Environmental Impact

Is HDPE conduit recyclable or environmentally friendly?

Yes. HDPE can be recycled through standard industrial recycling programs. Combined with our reel return initiative, it offers an environmentally responsible choice for conduit installations.

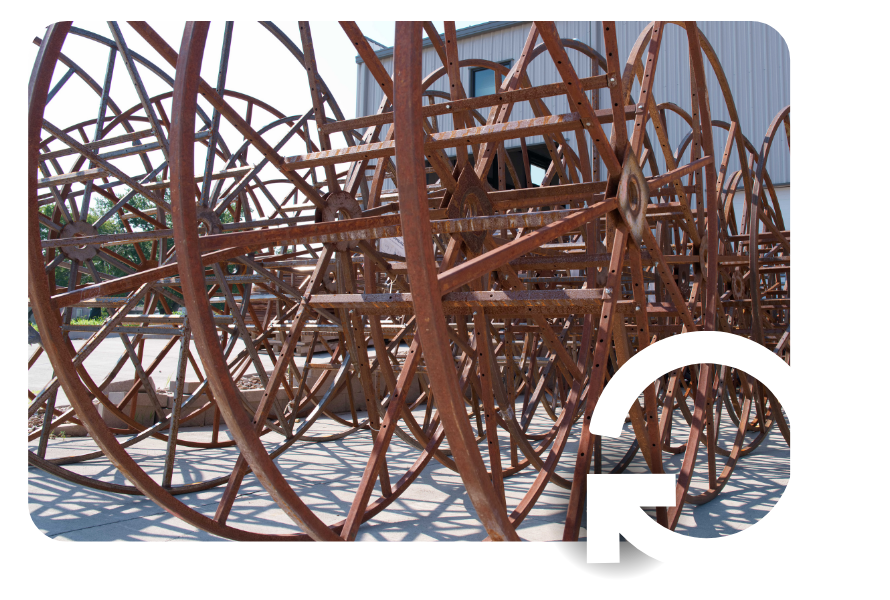

What is the reel return program?

Our Reel Return Program allows customers to return steel reels that meet our Acceptable Guidelines in exchange for cash. This reduces waste, promotes reuse, and keeps job sites cleaner.

Customer Support & Warranty

What warranty or support options are available with HDPE conduit purchases?

While we do not list a formal warranty, we stand behind the quality of every product. Each conduit is tested for performance and compliance with ASTM standards. Our in-house sales and support team is available for technical guidance, project planning, and troubleshooting.

REEL RETURN PROGRAM

Locate reels that meet the Acceptable Guidelines and return them for cash. Reusing steel reels is environmentally friendly and cleans up the work area. Reels in good condition can be sent back to Conduit Direct Group for reuse.